Bambu Lab P2S Combo

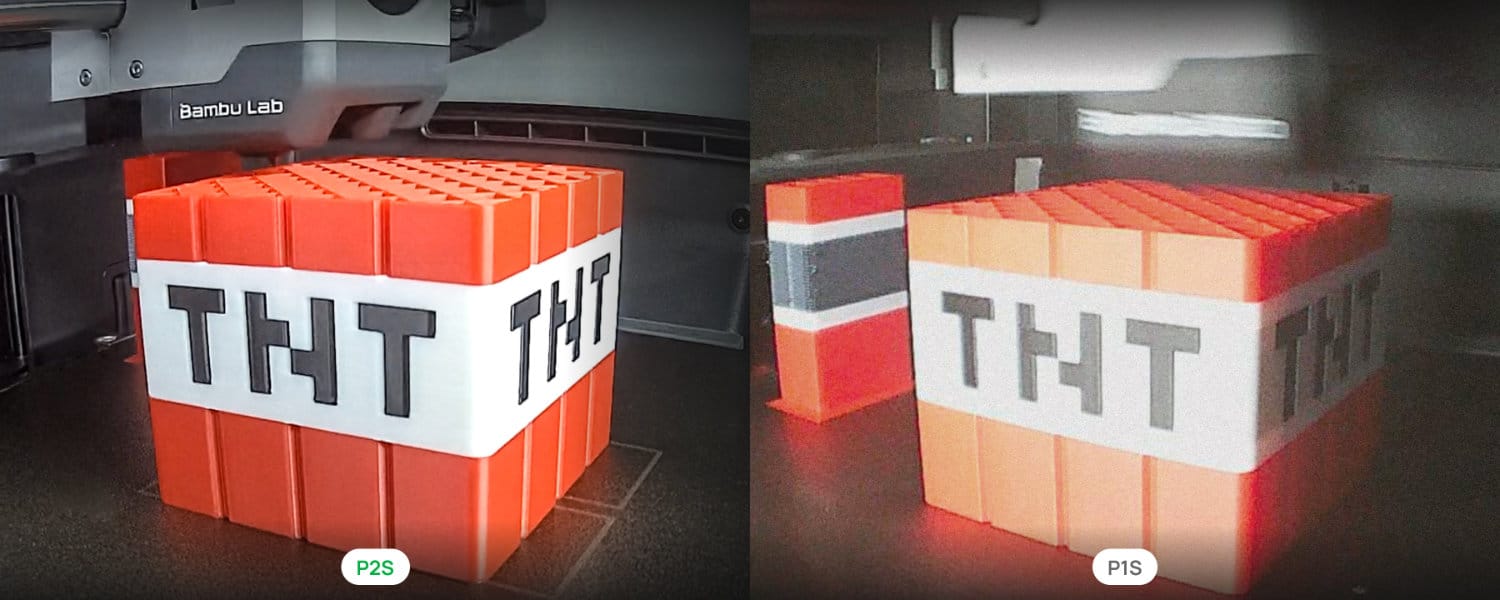

Next-generation precision and performance

The Bambu Lab P2S is designed for users who expect professional quality and reliability in every print. Its upgraded PMSM servo extruder provides stable extrusion and smooth filament flow, even at high speeds. Automatic flow calibration and AI-powered monitoring ensure consistently accurate results without the need for manual adjustments.

Smart design, effortless operation

With its intuitive 5-inch touchscreen and redesigned interface, the P2S makes advanced printing simple. Clear menus and step-by-step guidance make setup, calibration, and monitoring easy for all users. It’s a machine that feels smart, fast, and ready to deliver from day one.

Adaptive Airflow system

The innovative Adaptive Airflow system automatically manages temperature and airflow inside the chamber. It keeps the environment ideal for each material – maintaining heat for technical filaments or introducing cool air for PLA and PETG. The result is stronger layer bonding, smoother surfaces, and more reliable printing overall.

Built to last

With a durable steel and glass frame, precision mechanics, and high-quality components, the P2S is built for long-term reliability. Quiet, consistent, and powerful – it’s a dependable tool for professional studios, schools, and creative makerspaces alike.

2nd-Gen UI on 5-Inch Touchscreen

The P2S comes with a fully upgraded touchscreen and a powerful processor running our intuitive second-generation UI. It offers smoother interactions, richer graphics, and clearer step-by-step guidance. Simple, intuitive, and easy to use—even for beginners.

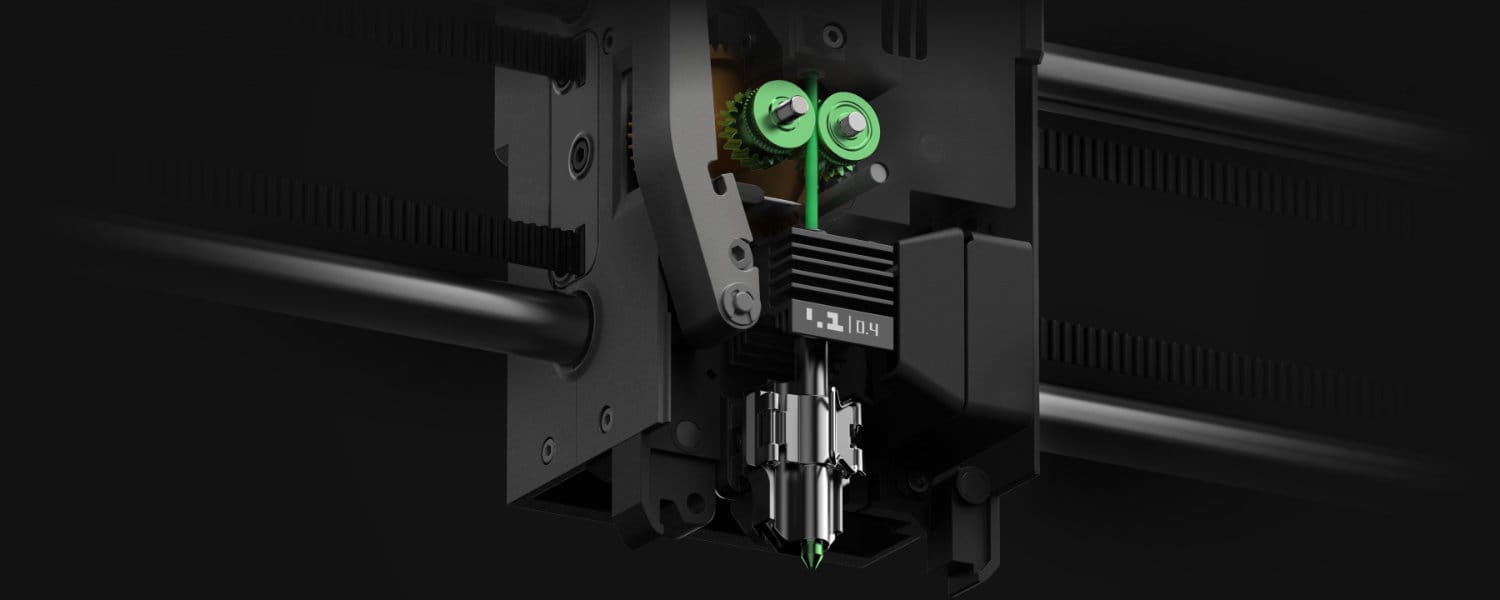

PMSM Servo Extruder

The PMSM servo extruder delivers up to 8.5 kg of maximum extrusion force – 70% more than its predecessor – dramatically improving stability at high flow rates. Moreover, our servo architecture samples resistance and position at 20 kHz, actively detecting filament grinding and clogs in real time.

Auto Flow Dynamics Calibration

The P2S uses a high-resolution, high-frequency eddy current sensor to calibrate flow dynamics. Intelligent algorithms actively adjust the flow rate based on these readings, ensuring precise, consistent extrusion across every layer and corner.

Adaptive Airflow Cooling

The Adaptive Airflow System draws in cool air directly from outside the chamber, significantly improving cooling efficiency. This allows users to print low-temperature filaments with the doors closed – without compromising overhang quality or risking nozzle clogs.

Adaptive Airflow Heat Preserving

A flap-controlled Adaptive Airflow System efficiently retains heat within the chamber while filtering internal air through a high-performance carbon filter. This enables confident use of high-performance, warp-prone filaments while maintaining clean, safe air quality in the workspace.

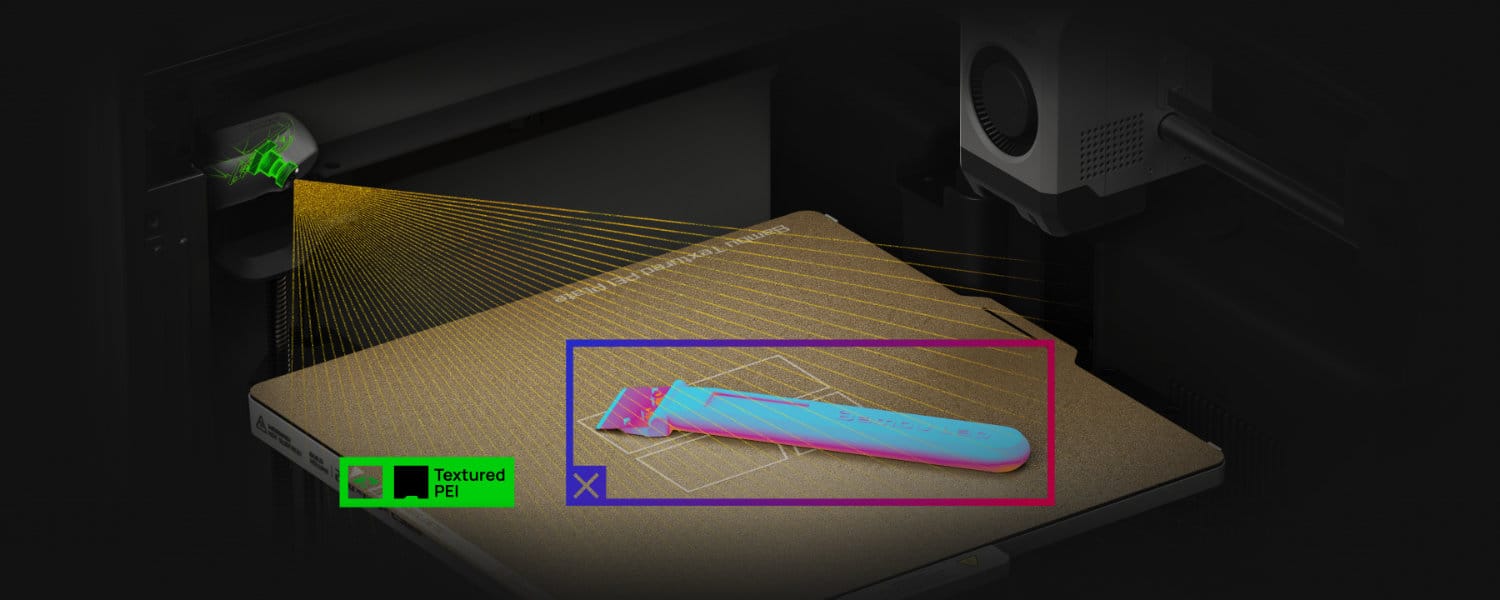

AI Error Detection

The P2S introduces advanced AI-powered computer vision that actively detects common printing issues such as spaghetti, nozzle blobs, and air printing. It also cross-checks the build plate and nozzle type against slicer settings, ensuring a safe and accurate start to every print.

1080P High-Rate Live View

Enhanced LED lighting dramatically improves the clarity of live video and timelapses. Paired with a high-frame-rate camera, users can easily monitor the printer remotely and capture stunning timelapses for social media sharing.

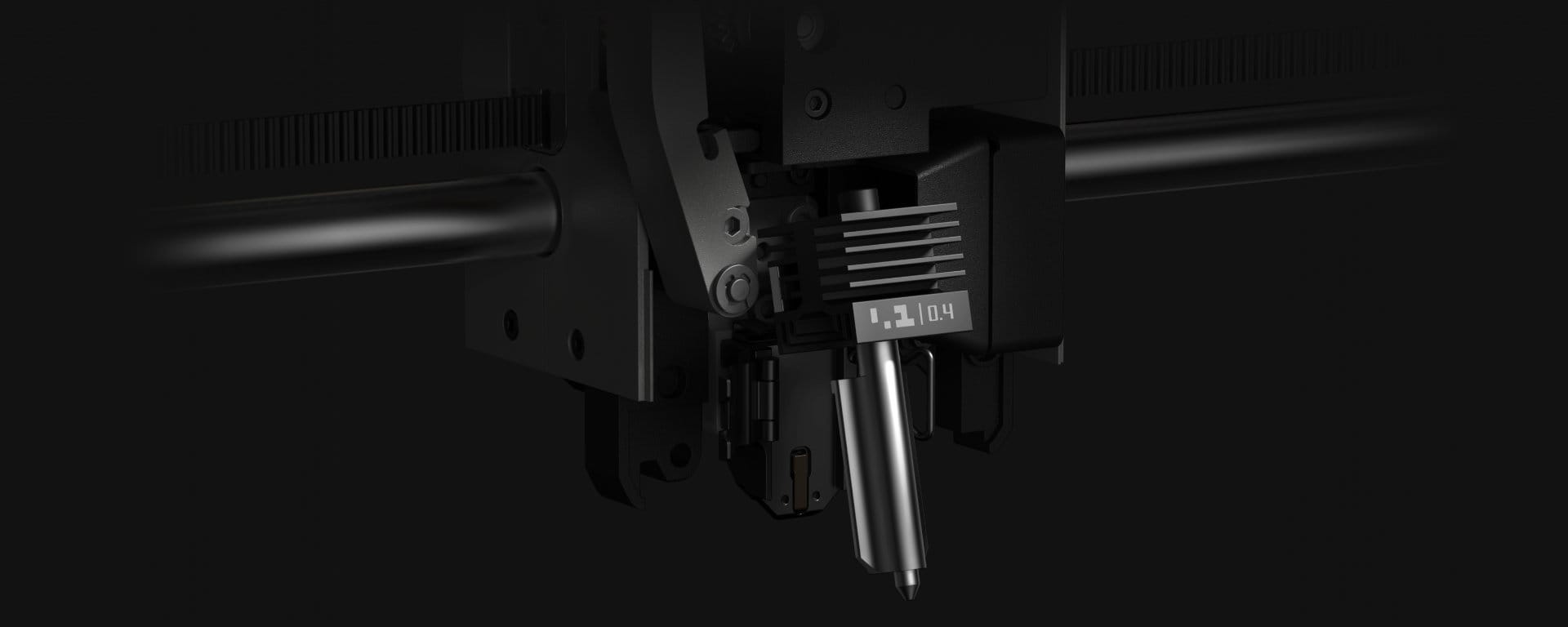

Quick-Swap Hotend

The P2S features a quick-swap nozzle design with a simple one-clip mechanism that releases the entire nozzle and heatsink assembly – no wiring connections required.

AMS 2 Pro

The P2S Combo comes equipped by default with the highly reliable multi-color AMS 2 Pro system, featuring enhanced filament drying. A pioneering active venting system dries filament 30% faster than sealed heating, maintaining low humidity for superior storage and print quality.